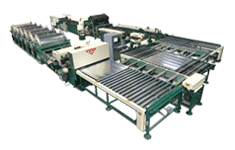

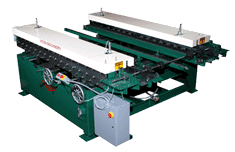

Automatic Duct Liner Application System

Model V-510-DD

The Vicon Automatic Duct Liner Application System uncoils duct liner, applies liner adhesive to the sheet metal and automatically pins the liner to the sheet metal. This machine can work with various types of liner including but not limited to Armaflex® and K-Flex® insulation.

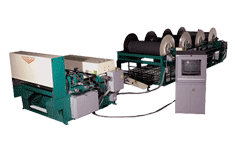

Optional four-position insulation coil holder (shown to the right) is for long runs of the same liner or short runs of different liner. You benefit in both situations. Down time is greatly reduced between insulation changeovers with preloaded coil holders.

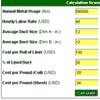

ViSoft Software is menu-driven, user-friendly and can be set to SMACNA standards or customized to your shop standards. Continually updated and supported by Vicon's experienced team of programming engineers, ViSoft ensures enhanced productivity and superb part accuracy.

- Push button control allows fast, safe and easy threading and crop cutting.

- Heavy duty liner shear with double-sided D-2 shear blade for extended life.

- The shear and feed can work with various types of liner including but not limited to Armaflex® and K-Flex® insulation.

- Rows of pins spaced to SMACNA standard for low and high velocity air flows (pin placement can be customized via the control system).

- Unit automatically controlled by the Vicon Control System.

- Easy, open access to glue heads for cleaning.

- 72" coil capacity

- Four position insulation coil holder to allow for rapid change of insulation sizes.

- Automatic adhesive extrusion application system.

- Multi-speed drive for optimum pinning speed or bypass of unlined duct.

- Designed to apply 44", 47", 48", 56", 59" and 60" wide liner.

- This machine can work with various types of liner including but not limited to Armaflex® and K-Flex® insulation.

- Low profile liner cradle / uncoiler

- Multi-head pin spotter: choice of Duro-Dyne® or Gripnail®

Other machines you might be interested in: