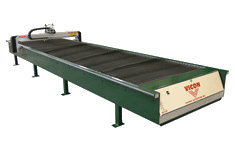

HVAC 520-DL Plasma / Liner Cutting Table

Sheet Metal/Duct Liner Combination Cutting System

Versatility to the maximum! Cut metal or liner without any setup. Cut your metal on bed 1 and your liner on bed 2. You can also convert the machine to cut metal or liner on the entire 20 plus foot cutting area. The new Vicon patented process automates duct liner cutting, making it clean, dry, fast, smokeless and accurate. In addition, liner waste is greatly reduced adding to the increased profits.

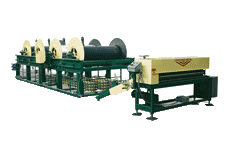

With the patented Bar Code Scanning option, sorting problems are a thing of the past. Coordinating the flow of sheet metal and duct liner through the shop is made much simpler and faster. Sheet metal parts are scanned, and the machine is automatically programmed to produce the corresponding downsized duct liner. Superior true-shape nesting minimizes waste.

- Combination machine cuts both sheet metal and duct liner with precision accuracy on the same table

- For users that need additional sheet metal and liner cutting capability

- Available in table sizes: 5'x10', 5'x20', 6'x10' and 6'x20'

- Robust, one-piece steel frame for strength, stability and easy installation

- Adjustable, quick-change torch holder - no tools are needed to change torch consumables

- A ski cup protects the torch tip from contacting the material

- Patented systems to hold and cut duct liner

- Automatic liner cutting and plasma cutting selection from Vicon controller

- Various torch options available for plasma cutting

- Synthetic table surface for smooth liner cutting

- Vicon HVAC Cutting Software produces two geometries - one for the sheet metal and another for the duct liner

- Dual rack and pinion drive on both axes for greater positioning accuracy

- Aluminum gantry results in "low inertia" for greater part accuracy

- Roller guides on both axes for greater rigidity, stability and accuracy

- Traversing speed up to 2,000 inches per minute

- Non-lubricating gears and bearings

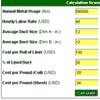

| Specifications | ||

|---|---|---|

| Effective Cutting Area | (Standard) (Optional) |

5'x20' 5'x10',6'x10',6'x20' |

| Material Capacity | 28 gauge to 1/2" thick plate |

|

| Machine Length | 288" | |

| Machine Width | (Standard) (Optional) |

90" 102" |

| Table Height | 35" | |

Other machines you might be interested in: